設備

Inspection, Testing Equipment

Black Bear parts are made from top grade raw material and high strength alloys. Sophisticated manufacturing equipment such as CNC Horizontal Machining Centers, Robotic Welders and Precise Scanning Probes, Automatic test system for motor are used to insure the highest consistency and quality. Once hoists are assembled, they are individually tested and inspected using automated equipment and strict quality control standards.

1) Specification :

- Weight range of work piece : 20 – 300kg

- Max. weight of same weight on each supporter : 500kg

- Belt drive : 100mm; Joint drive : 1300mm

- Distance between bearings : 2200mm Journal diameter : 130mm

- Balancing speed : Control by inverter (VF-11S TOSHBA)

- Measuring range : 300~20000rpm

- Sensitivity : 5μ

- Drive motor : 3.5kW (AC 220V 3PH WUTA)

2) Correcting tools for dynamic balancing

- Φ460 PM traction machine rotor Ass’y (rope pulley / ratchet wheel / magneto bushing)

- Φ560 PM traction machine rotor Ass’y (rope pulley / ratchet wheel / magneto bushing)

- PM Traction machine parts

Fabrication Equipment

Black Bear parts are made from top grade raw material and high strength alloys. Sophisticated manufacturing equipment such as CNC Horizontal Machining Centers, Robotic Welders and Precise Scanning Probes, Automatic test system for motor are used to insure the highest consistency and quality. Once hoists are assembled, they are individually tested and inspected using automated equipment and strict quality control standards.

1) Principle :

- Put coil in the oven temperature at 80℃for 2 hours.

- Put coil in the dipping tank and fully covered by insulating varnish.

- Lift the auxiliary tank up to main tank on soaking level.

- Solvent of main tank pours into the coil which becomes insulated. This is according to the principle of differential-temperature.

- Let varnish returns to auxiliary tank from main tank till it dry out.

- Open the cover and take coil out. Finish the process.

2) Applications :

- Φ160 Φ190 stator ass’y (Electric chain hoist)

- Φ190 Φ220 Φ260 Φ310 stator ass’y (Wire rope hoist)

- 0.4kW~3.7kW Soft start/stop reduction gear motor

- 0.25kW~1.5kW Planetary motor series

A) Operation steps :

- Main power control box “Main Circuit Breaker ON”. Machine “Control power ON”. Then press “Hydraulic ON” (Inlet air must be ON, check from “control power” OFF ON air sound. Or check the function of solenoid valve)

- Inlet valve B “ON”, Air Release Valve A “OFF”

- Press “Open cover”. After putting stators inside of Varnish tank, press “Close cover”

- Inlet valve B & Air Release Valve A “OFF”

- Press vacuum pump “ON”. Air Release Valve A “ON”. (under the vacuuming)

- After “Vacuum timer” reaches 420 seconds, buzzer ON for 10 seconds. It means vacuum completely.

- Air Release Valve A “OFF”

- Press vacuum pump OFF. (Completion of vacuuming)

- Inlet valve B “ON” at 45°position.

- The tank starts balancing pressure. When it reaches 0.0 kg/cm2, carry on with next step.

- Air Release valve A “ON” at 45°position. “Vacuum indicator” reaches “0”, go to next step.

- Air Release valve A & Inlet valve B “OFF”.

- Press “Add pressure ON” (Add pressure valve ON. When tank pressure reaches pre-set 5 kg/cm2, maintaining pressure timer starts. When it reaches pre-set 1800 seconds, Add pressure valve “OFF” automatically. Relief valve “ON” automatically. When relief pressure timer reaches pre-set 850 seconds, buzzer ON for 10 seconds.)

- Inlet valve B “ON”. Check if there is pressure left. Go to next step as no pressure left.

- Press “Open cover” and take stator out from the varnish tank. The press “Close cover”.

- Inlet valve B “OFF”. Press Hydraulic OFF Control power OFF Main circuit breaker OFF.

B) Application :

- Φ90 stator Assy DC Brushless Chain Hoist

- Φ160 stator Assy Permanent Magnet Chain Hoist

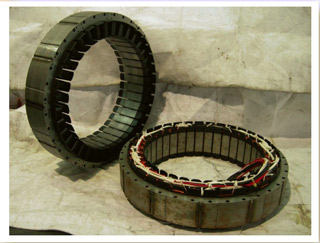

- Φ462/Φ560 stator Assy PM Traction Machine

1) Precautions :

- Check winding parameter setting

- Check winding coil diameter

- Measure stator stack height again

- Winding fixture selection according to specification of stator.

2) Winding specification :

- Φ 90 X 50 L Φ 90 X 25 L

3) Application :

- BLFD Permanent Magnet Brushless Hoist

1)Precautions :

- Check winding parameter setting

- Check winding coil diameter

- Measure stator stack height again

- Winding fixture selection according to specification of stator.

2) Winding specification :

- Φ 160 X 45 L Φ 160 X 30 L

3) Application :

- YSFD Permanently Magnet Brushless Hoist

1) Precautions :

- Check winding parameter setting

- Check winding coil diameter

- Measure stator stack height again

- Winding fixture selection according to specification of stator.

2) Winding specification :

- Φ 462 X 70 L Φ 560 X 75 L

- Φ 462 X 80 L Φ 560 X 90 L

- Φ 462 X 100 L

3) Application :

- Permanent Magnet Gearless Synchronous Motor Traction Machine

- Stator of BLFD in oven : Temperature : 70℃ / 12 hours

- Stator of BLFD in oven : Temperature : 120℃ / 8 hours

- PM traction stator in oven : Temperature : 120℃ / 8 hours