300 Kg Lever Chain Hoist

- Home

- Products

- Manual Chain Hoist

- Lever Hoist

- 300 Kg Lever Chain Hoist

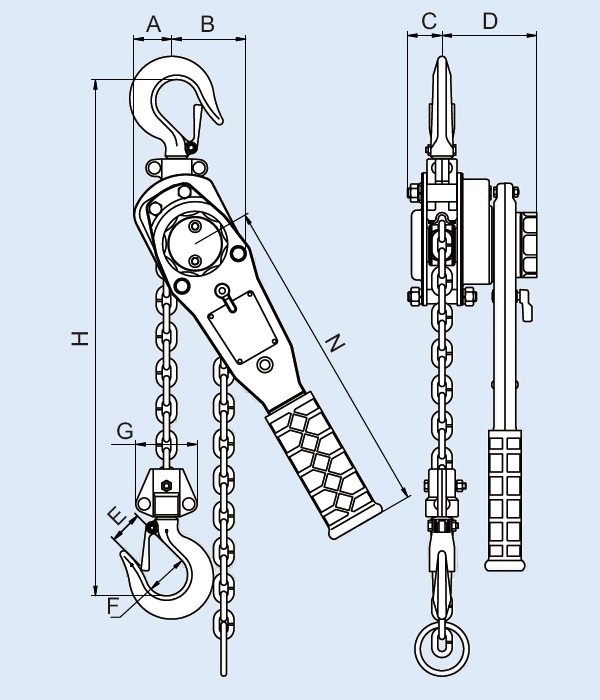

1.Steel Formed Cases

Both gear and hand chain wheel are protected by Hydraulic drew cases which is ideally shaped and rugged to be able to withstand external shocks.

2.Bushing

Bushing finished by surface hardened treatment and polish procedure serves to increase the mechanical efficiency and reduce the lever operation force.

3.Load Chain

Applying grade 80 alloy chain specially calibrates for manual hoists and conforms to ISO and DIN standard.

4.Chain Stopper

Work as the lower limit to prevent over traveling during lowering the load.

5.Chain Guide/Load Sheave

Ensure the load chain proper fitting the load sheave during operation and protect the load sheave from wet and dirt.

6.Hand Wheel

Allow an efficient chain length adjustment by switching the direction switch to“ free ”mold and rotating the hand wheel.

7.Brake Mechanism

No matter how heavy the load, the brake works instantly when operation stopped; the lining material is non-asbestos with long lifetime.

8.Dual Ratchet Pawls

Dual Ratchet Pawls are applied for extra safety purpose. In case one ratchet pawl fails, the other still maintains its mechanical brake function.

9.Top and Bottom Hooks Ass'y / Hook Housing

Hooks with hot forged and heat treatment allow to be swiveled 360゚ and are equipped with safety latch to ensure proper hooking the load.

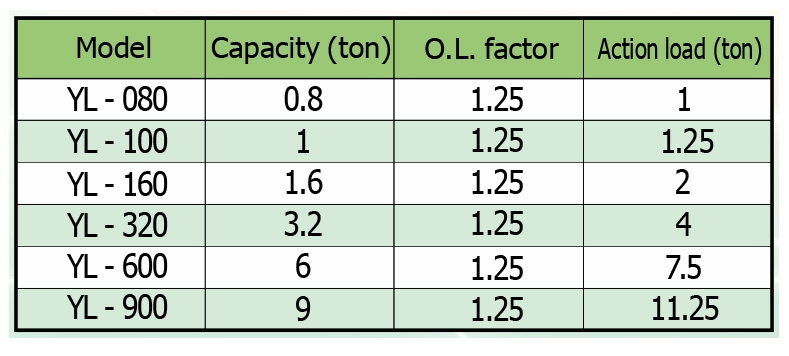

Advantage of Overload Device (O.L)-Optional

- New design of Overload Device with concealed structure protects itself from external effect.

- O.L. could work rapid and stable and be easily restored by reducing the load under rated capacity without readjustment.

- O.L. is manufactured by alloy metal and completed with surface hardness treatment to ensure long life operation.

- O.L is optional and could be attached onto the hoist without changing any hoist structure.

- Suggest using at frequent overload operation environment to ensure users' safety.

- Use overload device to ensure hoist life-span.